Effluent treatment facilities have to be built considering the absence of safely treated plus clean water that might have a direct unfavourable economical effect on commercial activities.

The following are some specific utilize for Effluent treatment manufacturing facilities:

1) Producing food & beverages preparation;

2) Boiler or cooling tower pre-treating apparatuses;

3) High-purity water pre-treating systems;

4) Bio-chemical pharmaceutical manufacturing;

5) Steam generation for humidification & electricity production & many additional applications.

Quite a lot reasons why ETP plants must be made compulsory to implement:

A) There is no scale formation or mineral deposition in hard water.

B) Contaminants are removed to improve beverage flavor, & water-applying equipment lasts farther & requires less maintenance.

C) Applications for it include single-point-of-utilization systems & centralized Effluent treatment plants.

D) In addition to two bigger pre-filters, it often features a strong, durable cleaning or filtering membrane or sheets with a cleaning mechanism.

The odor caused by organic particles accumulating on the purification filters is referred to as fouling. As this occurs, the pressure declines & the inward bound water flow are thus reduced. It cuts down the membrane's overall longevity & raises operating costs.

Pre-treatment only makes the process take longer. A simple filtration process is used to reduce the contaminants in the feedwater.

Scaling formation: Whenever there is a lot of water, we may all witness scaling layer formation in one form or another. More of the organic plus inorganic particles in the water begin to precipitate on various membranes or filtering films. As a result, solid undesirable layers start to build up as scaling. It reduces salt-rejection, pressure, & permeates exchanges. As consequently, the Effluent treatment plant system operates worse while the water quality eventually deteriorates.

Technical Operator Difficulties: Back loads plus sudden onset in the feedwater are two possible dangerous plumbing-related problems. Both of these could harm membranes. This can be set on by establishing changeable frequency motors fitted with check valves, or pressure relief-valves.

Chemical Interactions: Very lightweight membranes are now used in the designs of most Effluent treatment plant manufacturers. But the thin, fragile membrane are twice as prone to damage & assault, especially from poisons or pollutants like too much chlorine. These dangerous chemicals have the potential to damage the membrane irreparably by generating holes or fissures.

We can guarantee the customers we assist that every task we do is of the highest caliber since we place a high priority on excellent customer service & don't only think about the bottom line.

This is a short overview of Effluent treatment plant manufacturers producing premium ETP Plants.

1) Commercial RO Plant:

With its headquarters located in Gr. Noida, one of the largest ETP Plant manufacturing firms on the market provides its clients with outstanding service by connecting them with the company's professionals, who have undergone extensive training in each of these fields. Therefore, whether you want to purchase a ETP plant, its equipment, or associated services, this is a company to take into consideration among the Effluent treatment Plant Manufacturers.

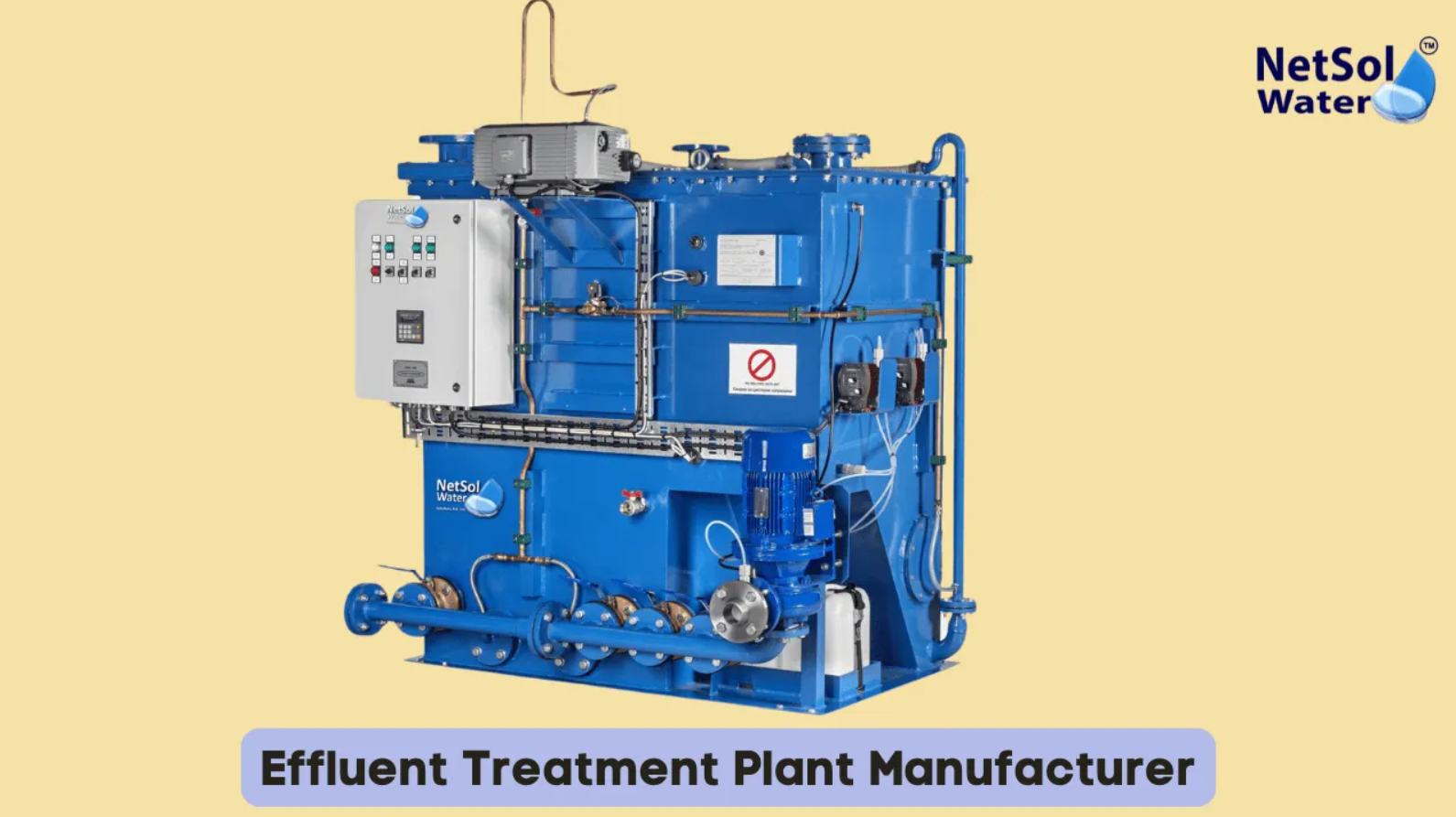

2) Netsol Water:

Surrounded by several water-refining roles, this firm has a well-built-base-reputation for bringing unrivalled building of ETP Systems & its delivering services for advanced commerces or facilities along with different related equipment, as well as a thorough troubleshooting system with round-the-clock assistance line.

3) Urban STP Plant:

Apart from functioning as a trusted name for ETP Plants, Urban STP Plant defines the best standard in manufacturing ETP Plants alongside offering excellence in water treatment apparatuses. Professionals with the expertise & tools needed to help & motivate people in a compassionate environment are always on hand here. When consumers buy various kinds of such water treatment plants together with related assets, facilities, plus services, they answer whatever inquiries they could possess & make sure they are comfortable.

4) Sewage Treatment Plant:

As an industrial-based ETP treatment company, Sewage Treatment Plant has completed all of its projects since its founding in 2012. It provides skid-mounted, electricity operated ETP plant systems with a capacity starting from 1000 upto 1,000k LPH. Additionally, they offer the greatest possible options for communal drinking water.

5) Commercial RO Plant Manufacturer:

The commercial RO plant manufacturer's manufacturing facilities use advanced multi-staged Effluent treatment in combination with refining RO, & UV+UF to make motorized or skid-mounted ETP Plant systems, even though they are best known for their household water purifiers.

Conclusion

As pointed out earlier while discussing, the Effluent Treatment Plant Manufacturers provide a variety of machinery items, including full installation that comprises pre-treatment supplies & equipment. Filtration systems, softeners, activated carbon, & anti-scalant chemical compounds are a few examples. This inexpensive technique may greatly extend the lifespan of Effluent treatment systems.

Commercial RO Plant & companies are the most significant source of Effluent treatment plants and all of India. Additionally, their company is one of nation's favourite manufacturers of Effluent treatment plants. We offer a variety of water treatment plants, wastewater treatment plants, and much more in addition to our trustworthy ETP plants. Get in contact with us if you need any help with any type of treatment of wastewater, including residential plus commercial or industrial Effluent treatment plant systems.

Write a comment ...